CNC Horizontal Milling Centers

Capacity

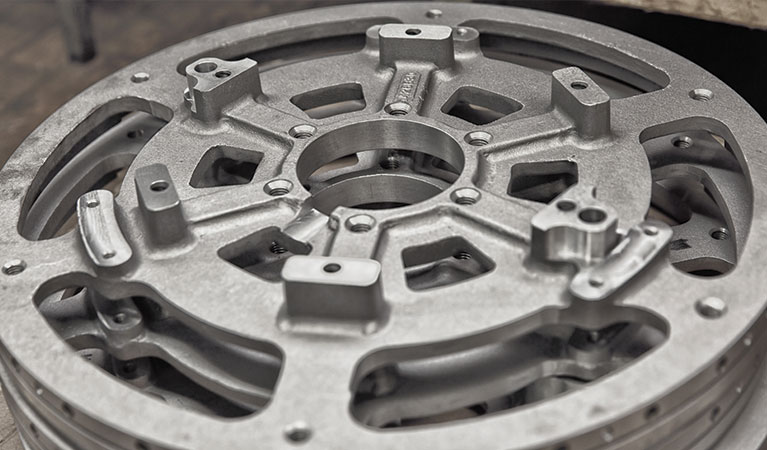

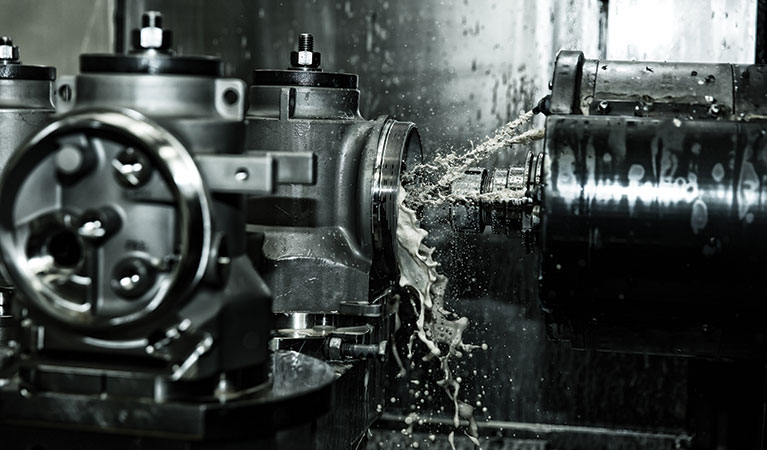

D&B Machining has some of the most experienced machinists in the New England area. Bringing over 85 years of combined experience to D&B, our team of CNC Horizontal Milling machinists is able to tackle some of the most complex parts across various industries. In conjunction with Lean manufacturing practices, the vast knowledge of CNC Horizontal Milling Center machinists allows for efficient and precise completion of both low and high production orders. Our CNC Horizontal Milling Centers are set up with a full 4th axis and thru spindle high-pressure coolant. This enables our equipment to tear through an array of materials including but not limited to cast iron, aluminum, bronze, carbon steel, Monel, brass, stainless steel, plastic, titanium, Inconel, and super duplex. We can machine and hold tolerances of (+/-.0002). Our six pallet Kiwa allows for lights-out operation, meaning the machine can and will run 24/7. By maximizing the running time of the Kiwa, the cost and lead time will be greatly reduced for our customers. If you have a project that requires the service of our CNC Horizontal Mill Centers, please contact D&B Machining. We look forward to working with you and exceeding your expectations.

(x1) Hitachi Seiki HC500

- Fanuc 6MB control

- Travel - X (28.00”) Y (25.00”) Z (22.00”)

- Spindle - 80-3,500 RPM, 15HP

- Automatic tool changer - 60 tools (50 taper)

- (x 2) 500mm pallets

(x1) Kia Center H63

- Fanuc 18iMB control

- Travel - X (37.40”) Y (32.50”) Z (29.90”)

- Spindle - 80-8,000 RPM, 30HP

- Automatic tool changer - 60 tools (50 taper)

- (x 2) 630mm pallets

- High PSI thru spindle coolant

(x1) Hyundai-Wia Center HS5000

- Fanuc 32iMB control

- Travel - X (33.50”) Y (27.60”) Z (29.50”)

- Spindle - 80-15,000 RPM, 30HP

- Automatic tool changer - 80 tools (40 taper - Big Plus)

- (x 2) 500mm pallets

- 1,000 PSI thru spindle coolant

(x2) Kitamura HX500i

- Fanuc 16i-MB control

- Travel - X (34.30“) Y (28.00“) Z (26.00“)

- Spindle - 80-10,000 RPM, 30HP

- Automatic tool changer - 50 tools (50 taper)

- (x2) 500mm pallets with full 4th axis

- High PSI thru spindle coolant

(x1) Kiwa KNH 426x

- Fanuc 18iMB control

- Travel - X (23.60”) Y (24.00”) Z (26.20”)

- Spindle - 80-12,000 RPM, 35HP

- Automatic tool changer - 120 tools (40 taper)

- (x 6) 400mm pallets with full 4th axis

- High PSI thru spindle coolant

- Marposs automatic tool setting probe

(x1) Okuma & Howa Millac 550H

- Fanuc 16i-M control

- Travel - X (31.50“) Y (31.50“) Z (27.60“)

- Spindle - 80-10,000 RPM, 40HP

- Automatic tool changer - 60 tools (50 taper)

- (x2) 550mm pallets with full 4th axis