Quality

Capabilities

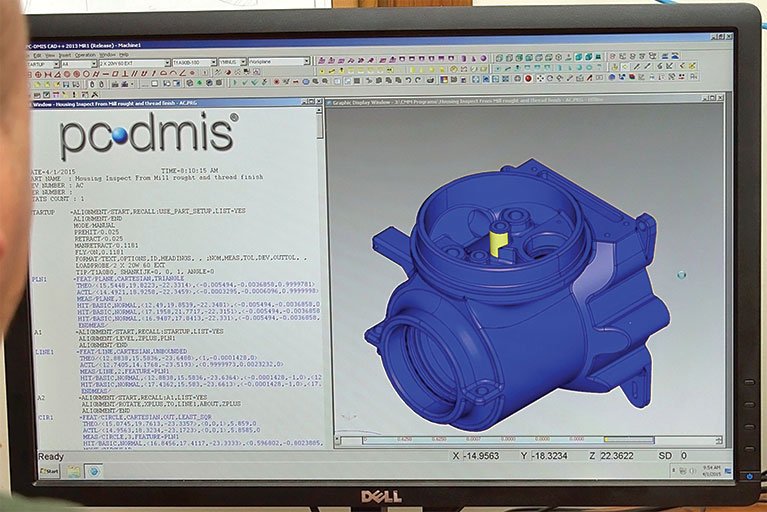

Working with our highly skilled team of machinists, the Quality Control Department at D&B strives to provide customers with precision parts that not only meet but exceed expectations. Under the supervision of our highly experienced Quality Control Managers parts are inspected in our temperature controlled Quality Control Department utilizing the latest inspection equipment and techniques. In order to achieve the highest levels of precision, D&B’s Quality Control Department Utilizes a Coordinate Measuring Machine (CMM). With the CMM, our expert Quality Control Managers can easily inspect a part within (+/-.00005") and provide an easy to understand color-coded report to show dimensions are within the customer’s required tolerances. The color-coded reports allow for employees and customers to review the in-process and final inspection reports with ease. D&B is also proudly ISO compliant and strives to exceed quality manual and standards. Information and calibration records are documented and revision controlled using a full Material Requirement Planning (MRP) system designed by E2 Shop Systems. D&B Machining is a top supplier in all categories and reports better than 98% in quality control testing. All of D&B’s employees take pride in the products they manufacture and the service they provide to all our customers. If you require unmatched service and attention to detail, please contact D&B Machining today.

Coordinate Measuring Machine, Inspection Equipment & MRP/Quality Software

- Giddings & Lewis Coordinate Measuring Machine (CMM) with PCDMIS software

- Tesa Hite 700, digital height gage (x2)

- Mahr Federal surface profilometer

- Mahr Federal dial gages

- Mahr Federal gage block sets

- Starret surface plates 48" x 96" (x2) and 18" x 24", many other different sizes

- Mitutoyo height gages 0"-12"

- Mitutoyo height gages 0"-18"

- Mahr Federal drop indicators

- Digital verneirs 0"-6" & 0"-12"

- Various sizes of intro micrometers & tri micrometers

- Depth micrometers 0"-6"Deltronic pins (.0001") increments

- Mitutoyo 0"-12" micrometers set (.0001") increments

- Thread ring gages and plug gages

- Hawkeye bore scope

- Visual comparator

- Starrett micrometer (.00005") increments

- Oko Seiki hardness tester

- E2 Shop System with barcode scanner/touch screen for real time tracking on manufacturing floor